Industrial Chemical Pumps in Tarrant, AL

Tarrant AL Drum Pumps

Drum pumps are utilized for a variety of industrial, commercial, and residential purposes that all entail transferring liquids from sizable drums or containers to other places where the liquid is needed. This involves moving liquids like water, oil, gasoline, and a variety of other kinds of chemicals. Drum pumps are useful for filling containers and for use in manufacturing because they can dispense fluids in precise volumes.

Drum pumps are widely used in a variety of sectors, including industrial, agriculture, and mining. Drum pumps are used in chemical processing businesses for things like food processing and pharmaceuticals. Drums are a common container in the water treatment and construction sectors, hence these businesses also employ drum pumps.

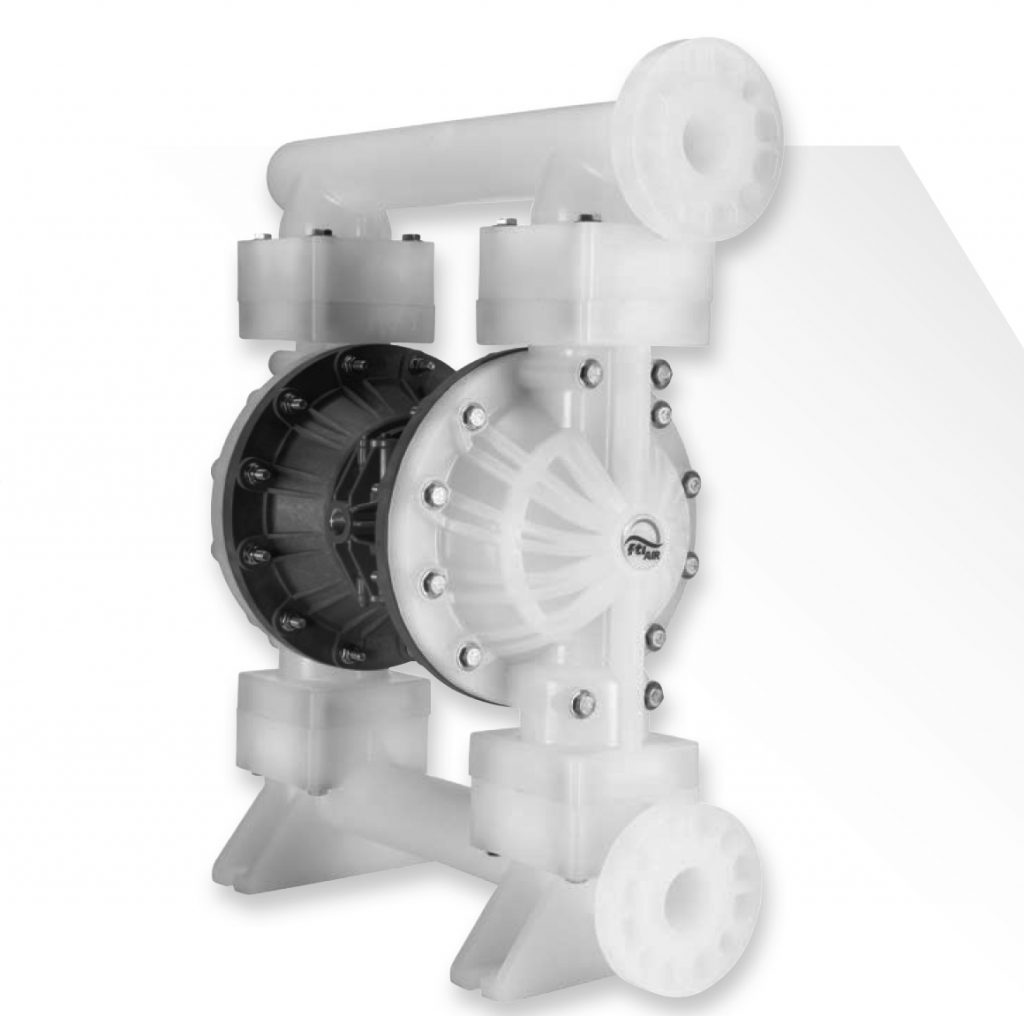

Air-Operated Diaphragm Chemical Pumps are Durable, Reliable, and Easy to Maintain

These pumps can move a wide range of chemicals, both acidic and alkaline, reliably and with the least amount of maintenance. Because they are powered by air, they can be used in dangerous places because they can't explode and don't have any electrical parts. Air-Operated Diaphragm Chemical Pumps are long-lasting and reliable pieces of equipment that can be used for a long time in harsh conditions.

Not only do these pumps need little maintenance, but they also have a system of air valves that keeps the flow rate and pressure consistent. They work well to move a wide range of chemicals without the need for priming or lubrication. Air Operated Diaphragm Chemical Pumps are very easy to maintain, making them an ideal choice for many chemical applications.

Tarrant AL Drum Pumps

Drum pumps are used for a wide range of commercial, industrial, and residential applications which all involve moving liquids from large drums or containers to other locations where the liquid is required. This includes transferring liquids such as water, oil, gasoline, and various other types of chemicals and liquids. Additionally, drum pumps can be used to dispense fluids in specific amounts, making them practical for filling containers and for uses in manufacturing.

Drum Pumps are popular in industries such as mining, agriculture, and manufacturing. Chemical processing industries rely on drum pumps for things like food proccesing and pharmaceuticals. Even water treatment and construction industries use drum pumps as drums are a regular container in these industries.

Tarrant AL Air-Operated Diaphragm Chemical Pumps are Durable, Reliable, and Easy to Maintain

These pumps can move a wide range of chemicals, both acidic and alkaline, reliably and with the least amount of maintenance. Because they are powered by air, they can be used in dangerous places because they can't explode and don't have any electrical parts. Air-Operated Diaphragm Chemical Pumps are long-lasting and reliable pieces of equipment that can be used for a long time in harsh conditions.

Not only do these pumps need little maintenance, but they also have a system of air valves that keeps the flow rate and pressure consistent. They work well to move a wide range of chemicals without the need for priming or lubrication. Air Operated Diaphragm Chemical Pumps are very easy to maintain, making them an ideal choice for many chemical applications.

Choosing the Correct Drum Pump in Tarrant AL

When selecting the ideal drum pump for a specific use, there are several factors that should be taken into account. These factors include:

- Price: Establish your spending limit and select a pump that satisfies your requirements at a cost you are comfortable paying.

- Safety considerations: Pick a pump that complies with applicable safety regulations and is suitable for the unique dangers prevalent in your application. Make sure the pump is explosion-proof, for instance, if you are transporting explosive liquids.

- Size and weight: Take into account the size and weight of both the pump and the drum or other container from which you will be transferring the liquid. Verify that the pump can fit inside the drum and is not too heavy to handle.

- Compatibility with the medium being transferred: Different models of drum pumps are specifically designed to handle different types of liquids. It is crucial to select the pump that is compatible with the type of liquid you need transported, as some liquids or chemicals can be too abrasive or viscous to work with certain models.

- Power source: Choose a pump that will meet the demands of your application and the type of power source you have available.

- Volume and flow rate: Consider both the volume and flow rate of the liquid you need to move. Ensure that the drum pump you select has a flow rate that meets your requirements.

Tarrant, AL Small Centrifugal Pumps and How They Work

Centrifugal pumps use a rotating impeller to move fluid through a system. This impeller, which is a disk with vanes or blades attached to it, is driven by a motor and the rotation exerts a centrifugal force that causes the fluid to move away from the center of the disk. Due to the difference in pressure caused by this movement, the fluid is drawn into the pump and moved through the system. In addition to transferring fluids, these pumps can be utilized to transport gases.