Industrial Chemical Pumps in Leeds, AL

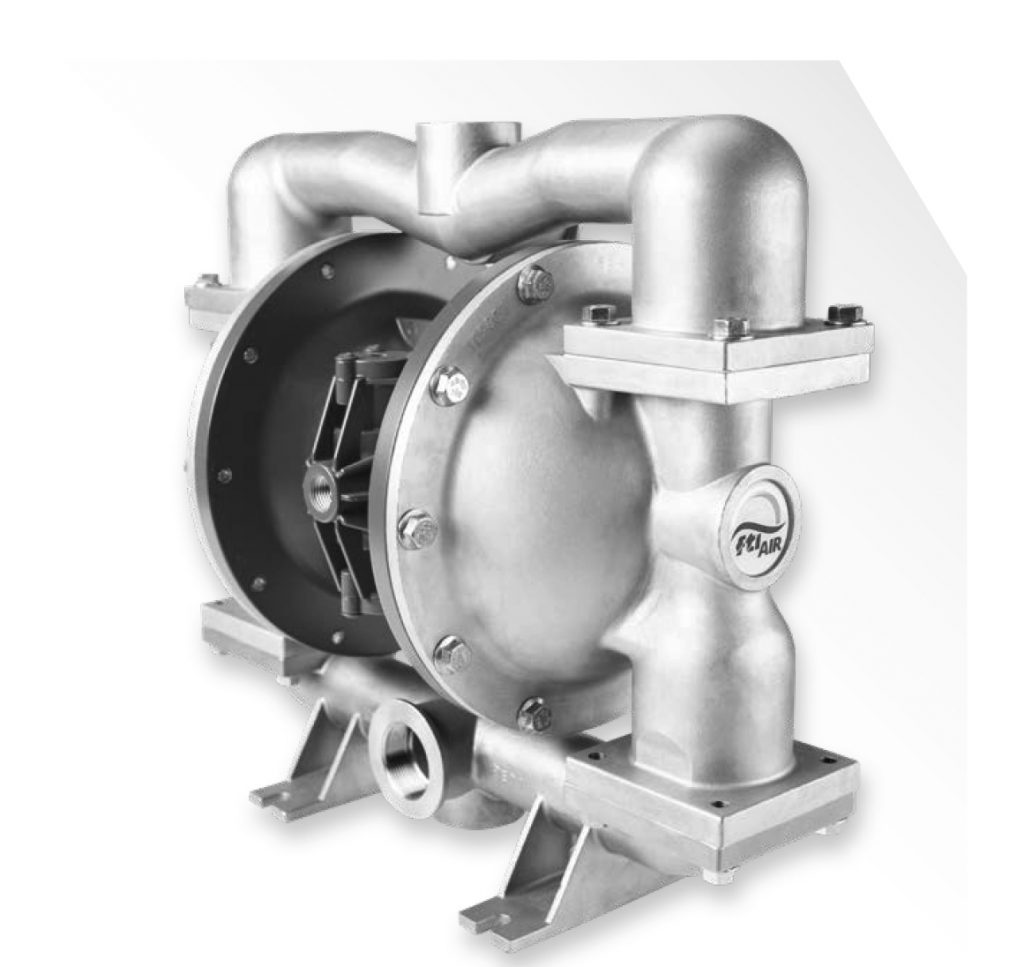

Air-Operated Diaphragm Chemical Pumps in Leeds, AL

Helping Industrial Leeds displacement pump needs.

Leeds AL Air-Operated Diaphragm Chemical Pumps are Durable, Reliable, and Easy to Maintain

These pumps can move a wide range of chemicals, both acidic and alkaline, reliably and with the least amount of maintenance. Because they are powered by air, they can be used in dangerous places because they can't explode and don't have any electrical parts. Air-Operated Diaphragm Chemical Pumps are long-lasting and reliable pieces of equipment that can be used for a long time in harsh conditions.

Not only do these pumps need little maintenance, but they also have a system of air valves that keeps the flow rate and pressure consistent. They work well to move a wide range of chemicals without the need for priming or lubrication. Air Operated Diaphragm Chemical Pumps are very easy to maintain, making them an ideal choice for many chemical applications.

Small Centrifugal Pumps in Leeds, AL

High flow rates and capacity to handle large volumes of fluid!

Drum Pumps in Leeds, AL

For transfering and dispensing fluids.

Leeds, AL Small Centrifugal Pumps and How They Work

Centrifugal pumps use a rotating impeller to move fluid through a system. This impeller, which is a disk with vanes or blades attached to it, is driven by a motor and the rotation exerts a centrifugal force that causes the fluid to move away from the center of the disk. Due to the difference in pressure caused by this movement, the fluid is drawn into the pump and moved through the system. In addition to transferring fluids, these pumps can be utilized to transport gases.

MSDB SERIES - MAGNETIC DRIVE, SEALLESS, Leeds CENTRIFUGAL PUMPS

- Heads up to 300 feet (91.5m)

- Compact close-coupled design

- Sealless design improves reliability with no seal maintenance to perform or seal leaks

- High specific gravity handling – over 1.8

- Horizontal or vertical (with IEC motor only) installation

- Minimum flow rate is 1 gpm (.23m3/h)

- Engineered for corrosive fluids with polypropylene/Ryton© or PVDF/Ryton© construction

- Maximum working pressure up to 135 PSI (9.3 bar)

- Two stage versions contain two impellers, three stage versions contain three impellers

- High power neodymium magnetic drive system handles high specific gravity fluids